Heat exchange equipment

Supplies of heat exchange equipment for various industrial sectors:

• Power engineering: cooling of main and auxiliary equipment of thermal power plants, combined heat and power plants, gas pumping units

• Oil and gas industry: cooling of high-temperature reactors, pipes

• Chemical industry: condensation of ammonia vapors

• Metallurgy: cooling of furnaces, rolling mills, casting machines and other units

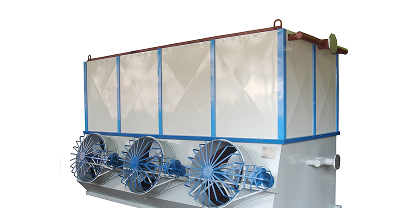

Air Cooling Units

ACU are designed for cooling and condensing gaseous, vaporous and liquid media in technological processes of oil and gas production, oil refining, petrochemical and other industries

At the customer's request, ACU are supplied with the following systems:

-

product supply and discharge

-

air recirculation

-

automated control

-

air humidifier, air heater service

-

platforms and auxiliary tools

Air cooling units (ACU ) are supplied in different configurations depending on their intended purpose:

-

for cooling gases and liquids

-

for condensing steam and vapor-liquid media in technological processes of the chemical, petrochemical, oil refining, oil and gas industries.

Specifications

The cooled medium can be under pressure up to 32.0 MPa or under vacuum with a residual pressure of at least 665

The temperature of the medium is not higher than 400 º

The device is designed for operation outdoors in macroclimatic regions with moderate and cold climate according to GOST (government standard) 15150-69. The supporting structure of the device is designed for installation in areas with seismicity up to 8 points and wind speed pressure according to the II wind region.

Horizontal ACU

ACU consist of horizontally arranged pipe sections made up of ribbed bimetallic pipes. The sections are mounted on a metal structure. The fan wheel drive is located on a separate frame.

Block-modular ACU

The device consists of pipe sections made up of bimetallic finned pipes. These devices are supplied assembled, which reduces costs and time for installation work.

Zigzag ACU

ACU consist of six pipe sections made up of bimetallic finned pipes. The sections are arranged in a zigzag shape at an acute angle to each other and to the horizontal support platform.

Custom-made ACU

The design of the air cooling apparatus is determined by the technical project.

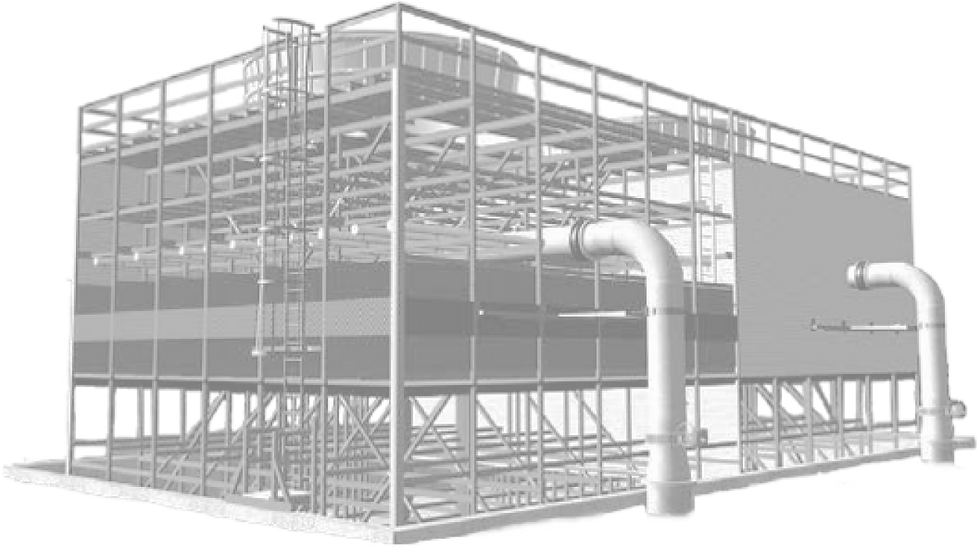

Cooling towers

Cooling towers are designed to cool and condense gaseous, vaporous and liquid media in technological processes in oil and gas production, oil refining, petrochemical and other industries. High-capacity cooling towers are used in circulating water supply systems to cool heat exchangers, in particular, at thermal power plants and nuclear power plants. In civil engineering, cooling towers are used, for example, to cool condensers of refrigeration units, in air conditioning, and to cool emergency power generators.

According customer's request, cooling towers can be equipped with additional elements and systems:

-

automation system (ACS)

-

including control panels

-

pumping equipment and instrumentation elements dispatch room special silencers for additional noise insulation entrances and platforms for installing fire trucks

Cooling towers are used to condense refrigerants in refrigeration systems and cool water in various technological processes. They are widely used in the energy, shipbuilding, aviation, chemical industries, metallurgy, mechanical engineering, food production, etc.

Fan cooling towers (centrifugal)

Used in many industries. The presence of control units and the possibility of drive reversal makes it possible to operate at negative air temperatures.

Industrial cooling towers

They are assembled on site and are characterized by significant power and are installed at facilities with high consumption of circulating water.

Small-sized cooling towers

Designed for enterprises with a small circulation cycle. Delivered assembled and ready for operation, do not require a special pool. Cannot provide deep cooling of circulating water (no more than 5-7 ℃)

Heat exchangers

The main trends in the energy sector are significant wear and tear of generating capacities and constant growth of consumption.

When modernizing and building new generating capacities, it is very important to use efficient and reliable heat exchangers.

Our specialists will help solve problems related to increasing the productivity of heat exchange equipment when replacing worn-out heat exchange equipment and heat exchange equipment of obsolete designs.

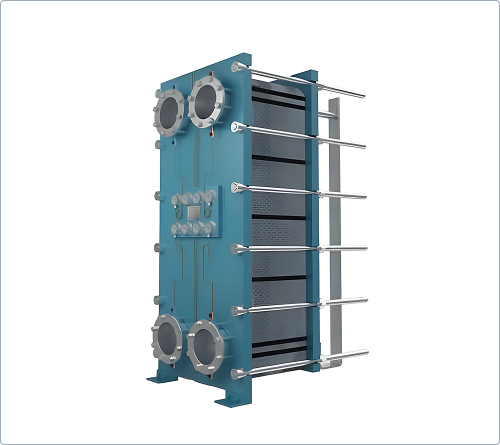

Disassemblable plate heat exchanger

The detachable plate heat exchanger can be disassembled and assembled, or individual elements can be replaced if necessary. The pins are unscrewed, the seals are removed, and the pressure plate is removed from the housing.

Advantages of detachable heat exchangers: maintainability and ease of maintenance. The plates can be washed separately, which opens up the possibility of using special washing machines and hoses, chemical solutions.

The detachable design allows you to add or remove plates, changing the power

immediately after pressure testing.

Technical specifications

Corrugation depth: 2.0 - 14mm

Maximum bearing capacity: 2.5MPa

Maximum angular aperture: 500 mm

Maximum single layer plywood area: 3.65m2

Maximum assembly area: 3800m2

Maximum capacity: 4200m3/h